Dynamic Rail Detection Device

Dynamic Rail Detection Device

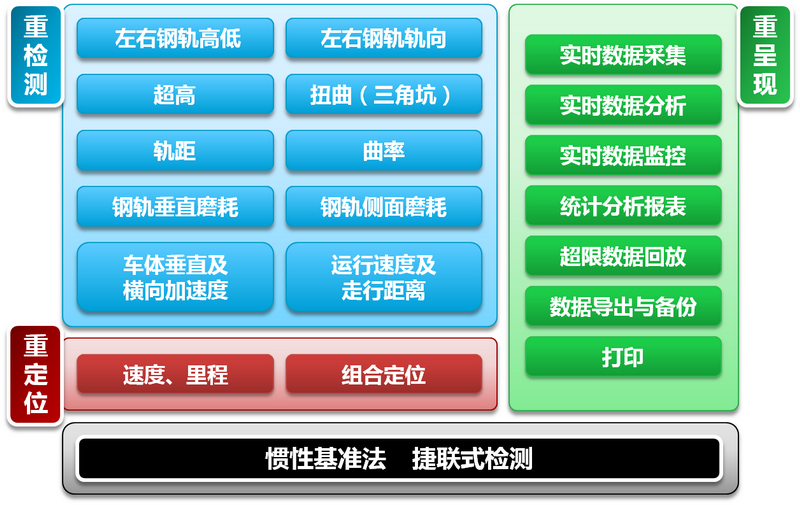

Re-detection, Re-presentation, Re-location

Product Description

Dinghan company has completely independent intellectual property rights for its detection product series of rail transit facilities, with 9 items of software copyrights and 24 items of patent pending. Among the proucts, dynamic rail detection device is used to conduct dynamic detection of superposition state of elastic deformation and permanent deformation for the line. It can also detect geometric state of rails, such as gauge, rail orientation, height, level (ultra-high), triangle pit, curvature; and state of rails, such as verticality of bodywork, horizontal vibration acceleration, rail surface wear, flank wear, total wear; and shortwave irregularity in rails, such as rail corrugation, surface abrasion; as well as environment items of railway, such as velocity, rail cant etc.

Product functions

Heights of left- and righ rails

Ultrahigh

Gauge

Vertical rail wear

Vertical and lateral accelerations of bodywork

Orientations of left- and right rails

Distortion (triangle pit)

Curvature

Rail flank wear

Running velocity and traveled distance

Re-location

Velocity, mileage

Integrated location

Re-presentation

Real-time data acquisition

Real-time data analysis

Real-time data monitoring

Statistical analysis reports

Ultralimit data playback

Heights of left- and righ rails

Ultrahigh

Gauge

Vertical rail wear

Vertical and lateral accelerations of bodywork

Orientations of left- and right rails

Distortion (triangle pit)

Curvature

Rail flank wear

Running velocity and traveled distance

Re-location

Velocity, mileage

Integrated location

Re-presentation

Real-time data acquisition

Real-time data analysis

Real-time data monitoring

Statistical analysis reports

Ultralimit data playback

Data export and back-up

Printing

Inertial reference method Strapdown detection

Product Features

Re-detection – Highly integrated installation

All the rail detection devices are integrated into the detection beams in the chassis and the internal control cabinets, achieving integration of installation and maintenance and that of analysis and presentation. It enables equipment performance mining by algorithms, which simplifies equipments, reduces costs and increases accuracy.

Re-detection – 12 layer-by-layer clutter filters

Through 12 filters including average recursive filter, first-order lag filter, the interferences of random errors on detection parameters, such as rail height, rail orientation, level (ultra-high), rail wear etc., are effectively inhibited, which ensures true reflection of rail state by detection curve.

Re-detection – Multi-dimensional dynamic compensation

Various dynamic compensation technologies are combined to perform dynamic compensation for all catenary detection parameters through horizontal and vertical components, which effectively reduced the impacts of bodywork hunting motion, nodding, rolling, vertical vibration etc. on detection results.

Re-location – Integrated location guiding repair work

“Speed Sensor+Database Location” is combined with multiple location methods, such as “Track Insulation Nodes Detection and Location Method”, satellite location and “Electric Tag Detection and Location Method”, to effectively improve accuracy of fault points locating, overcoming the limitations of poor location accuracy of “Speed Sensor+Database Location”in similar products.

Re-presentation – Detecting custom parameter settings

Curve display color, benchmark scale, unit, display properties and printing options of all detection items in the curve charts can be custom set, and ultralimit points standand can be set according to specific detection rating requirements of users, to meet the requirements of users on various combinations of inquiry, analysis, statistics of detection results, with flexible configurations and easy to operate.

Re-presentation – Multi-view real-time monitoring management

Real-time rail images recorded by multiple cameras can be simultaneously output by a single screen. Real-time correlations of data, charts and images are enbled by the master monitor, while different kinds of terminals can be used for monitoring, such as PC, monitors, TV sets etc., which ensues multiple-view synchronous monitoring of the rail state.

Re-presentaiton – Traceable ultralimit data analysis

Image recording and saving in 5 seconds before and after ultralimit points is supported. Overlapping comparison of curve charts between current detection data and the historical ones is enabled. It can be combined with expert evaluation system to implement normalized assessment of rail quality on the one hand, and provide scientific basis for subsequent repair work schedule according to the closed-loop situations of fault points to be repaired.

Re-presentation – Comprehensive data presentation management

Built-in expert evaluation system is used to perform statistic analysis of vast amounts of detection data, to generate real-time and non-realtime curve reports, tabular reports, ultralimit reports, with more complete and intuitive presentation of detection data, and efficient and accurate instructions of repair and maintenance work. Real-time and non-realtime printing, option printing, all-item printing and export of various detection reports are supported, as well as mass storage and dumping, such as hard disk recording and mobile storage etc.

Data export and back-up

Printing

Inertial reference method Strapdown detection

Overview of Product Models

| Application area |

Product Model |

|

Railway | |

|

Urban Rail Transit | CRTM -1 Dynamic Rail Detection Device for Urban Rail Transit |